#Healthforward

APPLICATIONS

TAILORED TECHNOLOGIES

In the world of health and wellness, every stage of the production process demands rigor, precision, and innovation. Doppel’s technologies are designed to meet these needs, ensuring quality, safety, and efficacy in every pharmaceutical application.

HARD AND SOFT CAPSULES

Production of capsules with a wide range of active ingredients, including sensitive or high-dose compounds, also available in vegetarian formats.

Each batch undergoes thorough testing to ensure product integrity, uniformity, and stability.

Solutions designed for small and large batches, adaptable to different markets and regulatory requirements.

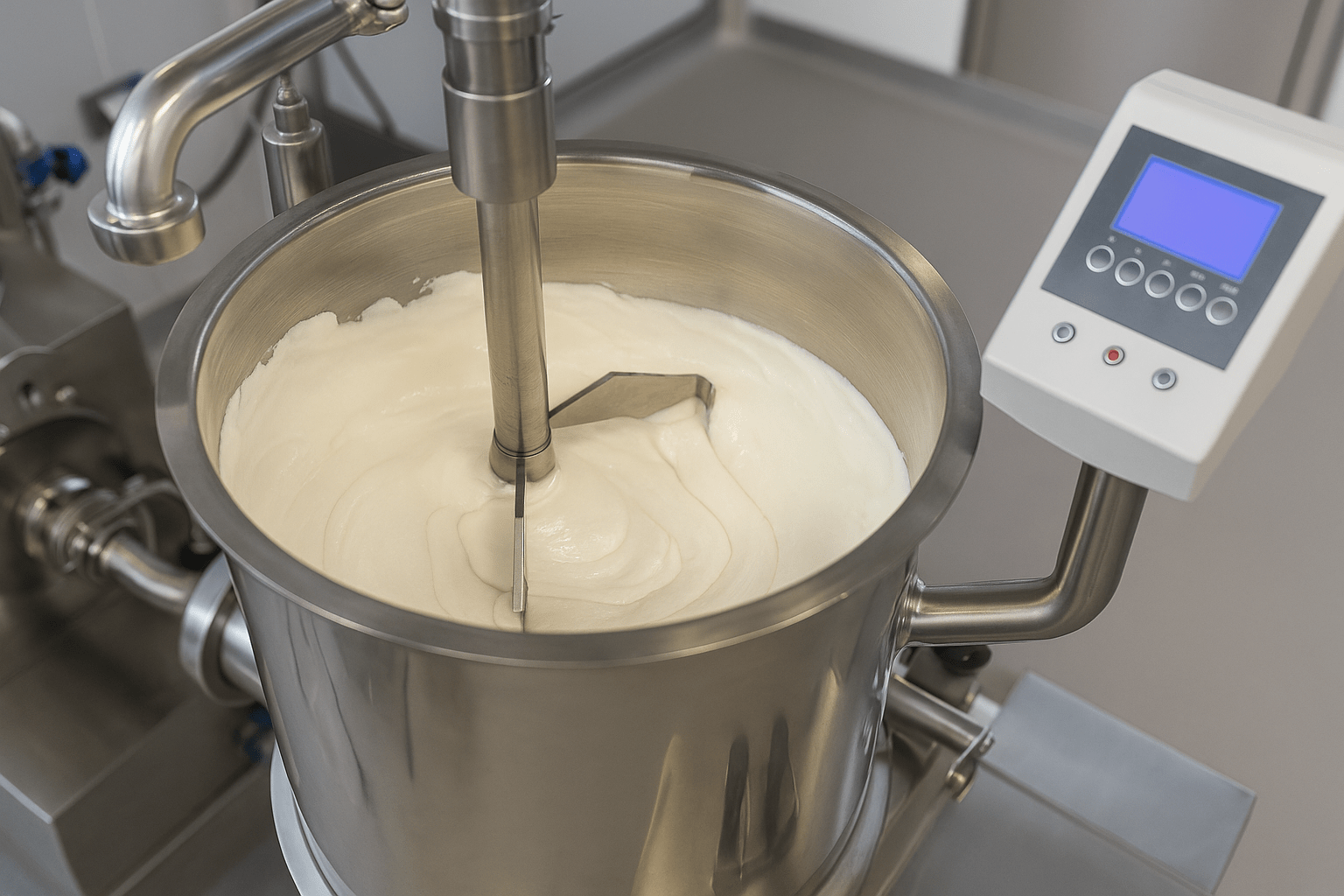

DEVELOPMENT OF SEMI-SOLID FORMULATIONS

Specific formulations for topical and mucosal use, developed to ensure efficacy and skin acceptability.

Production lines and facilities specialized in the processing of creams, gels, lotions, and suppositories.

Expert assistance in technical and regulatory documentation, from development to commercialization.

#Healhtforward

A SIMPLE METHOD

1. DISCOVERY SESSION

Every company is unique and has specific needs. During the initial meeting, we carefully analyze those needs to identify and design the solution to the project challenge.

2. REQUIREMENTS ANALYSIS

With our expertise in conducting formulation studies, we carry out a preliminary assessment to optimize the project and evaluate costs.

3. EXECUTIVE PHASE

Using the best technologies and the most effective methods, we implement the planned strategy and continuously monitor the process to ensure it aligns with the objectives and execution timelines.